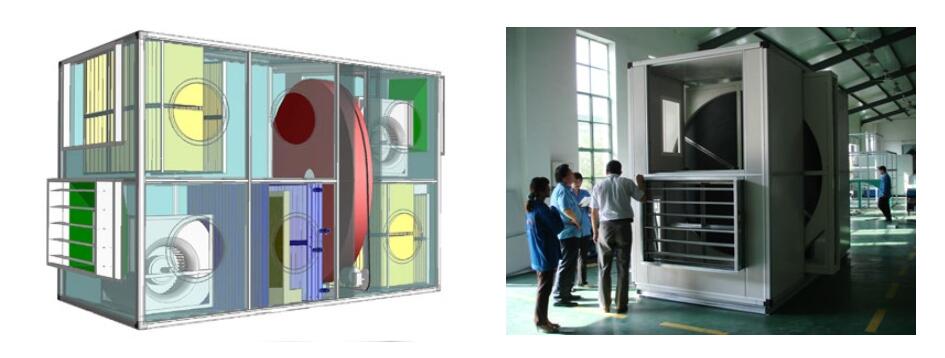

Rotary heat exchanger (Heat wheel) is mainly used in heat recovery building ventilation system or in the air supply / air discharge system of air conditioning system equipment.

The heat wheel transfers the energy (cold or heat) contained in exhaust air to the fresh air supplied to indoor. It’s one important section and key technology in the field of construction energy-saving.

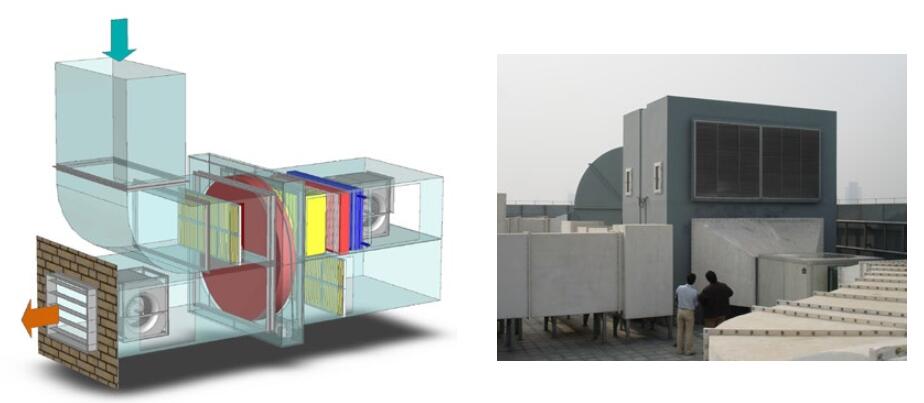

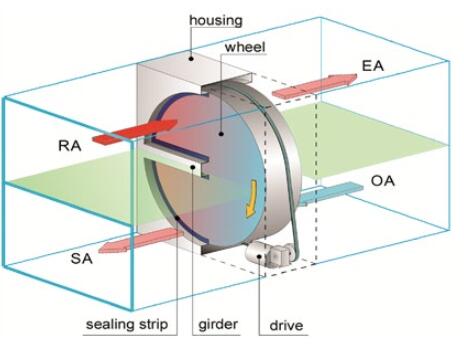

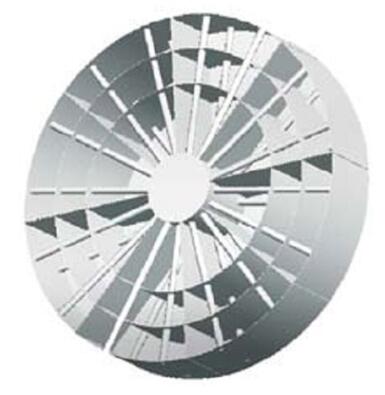

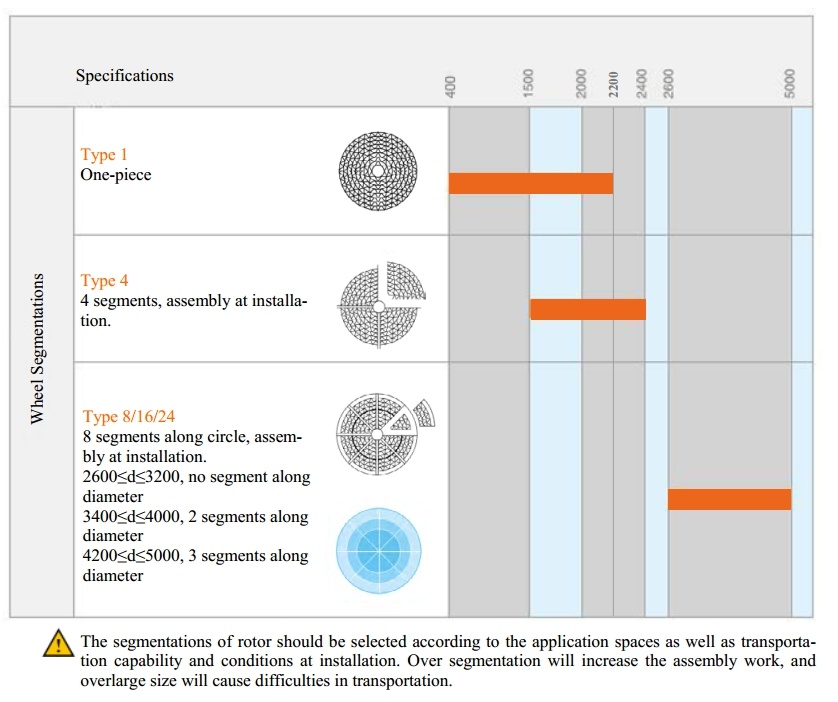

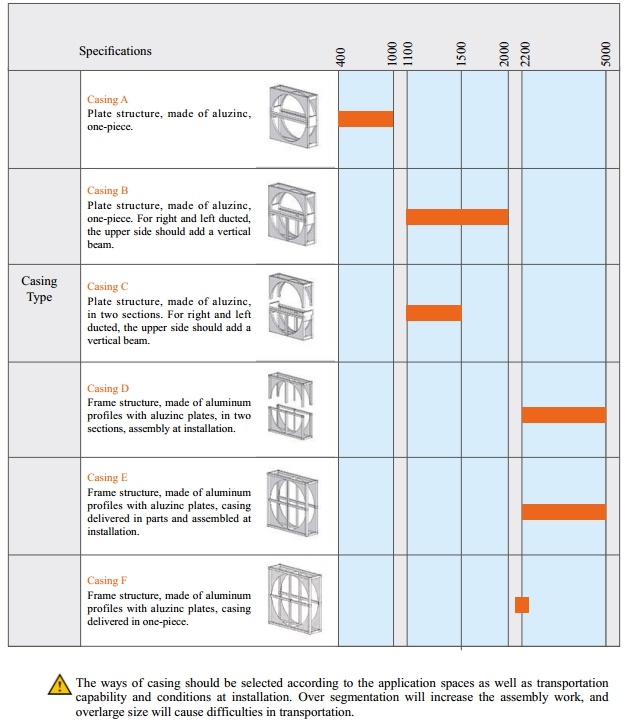

Rotary heat exchanger is composed of heat wheel, case, drive system and sealing parts. The heat wheel rotates powered by the drive system.

When outdoor air passes through half of the wheel, return air passes through reversely the rest half of the wheel. In this process, about 70% to 90% heat contained in the return air can be recovered to supply air to indoor.

Working Principle

Rotary heat exchanger is composed of alveolate heat wheel, case, drive system and sealing parts.

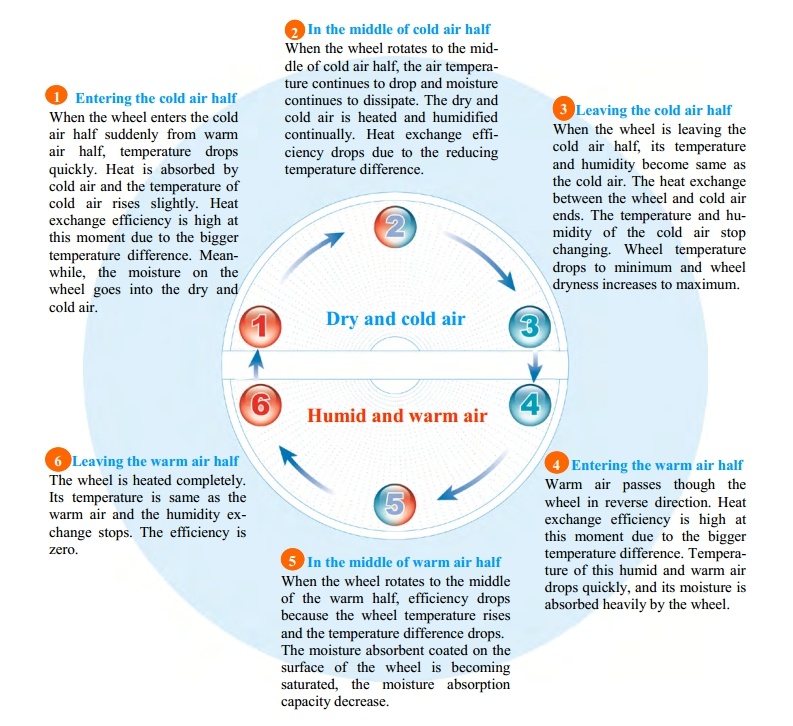

The exhaust and outdoor air pass through half of the wheel separately, when the wheel rotates,

The heat and moisture are exchanged between the exhaust and outdoor air.

The heat recovery efficiency is up to 70% to 90%

- Previous: Heat Pipe Heat Exchangers

- Next: Enthalpy Wheels

It can also be installed in the ducts of ventilation system as a main part of the heat recovery section, connected by

It can also be installed in the ducts of ventilation system as a main part of the heat recovery section, connected by