Quality Inspection for China Supplier Plate Heat Exchanger Core - Liquid Circulation Heat Exchangers – Holtop Detail:

Liquid Circulation Heat Exchanger -Heat recovery core of AHU

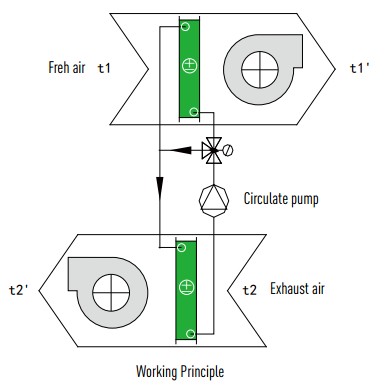

Working Principle

Liquid circulation heat exchanger is liquid to air heat exchanger, heat exchangers usually installed in both fresh air (OA) side and exhaust air (EA) side, the pump between the two heat exchangers make the liquid circulate, then the heat in the liquid pre-heat or pre-cool the fresh air. Normally the liquid is water, but In winter, in order to decrease the freezing point, moderate ethylene glycol will be added into the water in reasonable percentage.

Features of Holtop Liquid Circulation Heat Exchanger

(1) Fresh air and exhaust air heat exchanged by separated liquid pipes, zero cross contamination. It suitable for heat recovery energy saving of air handling system of hospital, germfree lab and industries which discharge poisonous and harmful gas.

(2) Stable,reliable and long service life

(3) Flexible connection between fresh air and exhaust air exchangers, easy installation, which also is convenient for old AHU improvement.

(4) Heat exchangers are conventional, easy and low maintenance costs.

(5) Wide range of application, various connection methods like one to one, one to more, or many to many.

Specifications

(1) Liquid circulation heat exchangers is sensible heat exchangers, efficiency is between 55% to 60%.

(2) Suggested rows number in 6 or 8, face velocity not over 2.8 m/s

(3) The choice of circulating pump can refer to the fresh air and exhaust air pressure drop and the water flows pressure drop.

(4) Air flow direction has significant effect on the heat recovery efficiency, influence rate up to 20%.

(5) Freezing point of the hybrid ethylene glycol and water should be 4-6 ℃ lower than the local minimum outdoor temperature of winter, percentage of hybrid can be referred to the following table.

| Freezing point | -1.4 | - 1.3 | -5.4 | -7.8 | -10.7 | -14.1 | -17.9 | -22.3 |

| Weight percentage (%) | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

| Volume percentage (%) | 4.4 | 8.9 | 13.6 | 18.1 | 22.9 | 27.7 | 32.6 | 37.5 |

|

|

- Previous: Combine Air Handling Units AHU

- Next: Heat Pipe Heat Exchangers

Product detail pictures:

Related Product Guide:

Sticking for the belief of "Creating items of top of the range and creating buddies with people today from all over the world", we normally put the interest of shoppers in the first place for Quality Inspection for China Supplier Plate Heat Exchanger Core - Liquid Circulation Heat Exchangers – Holtop , The product will supply to all over the world, such as: Stuttgart , Switzerland , Vietnam , Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.